Modbus Data Logger.

DAT9011DL

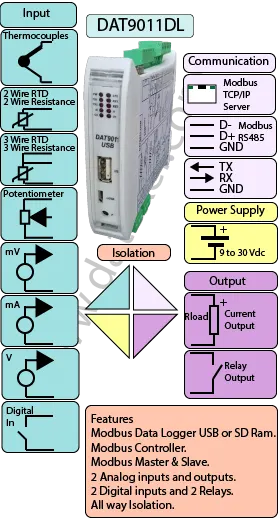

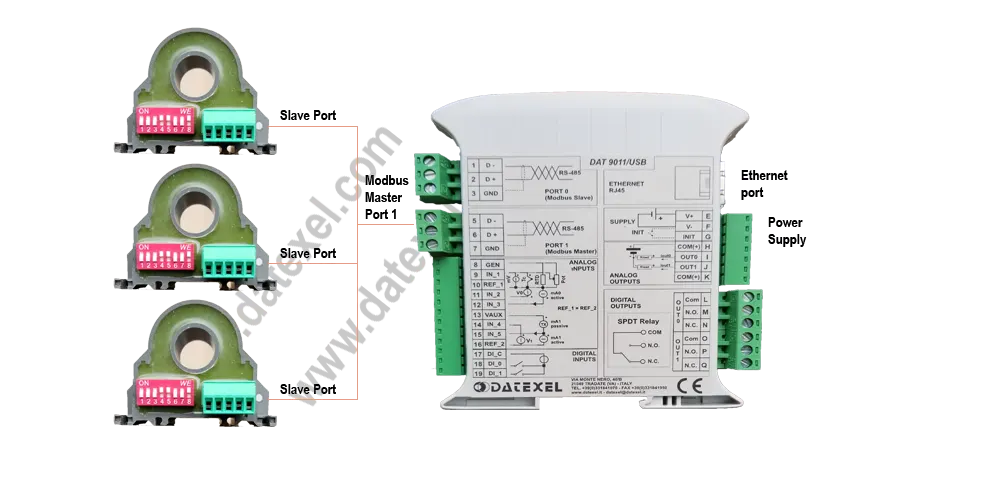

The DAT9011DL and DAT9011USB are Modbus data-logging and data-acquisition controllers that can store selected registers from a Modbus network as well as internal channels. The DAT9011DL logs to an SD memory card, while the DAT9011USB logs to a USB flash drive.

Both variants include on-board I/O: universal analog inputs (Thermocouple, mA, Volts, mV, RTDs, Resistance, Potentiometer), two 4–20 mA analog outputs, two digital inputs (up to 300 Hz), and two relay outputs for alarms/interlocks.

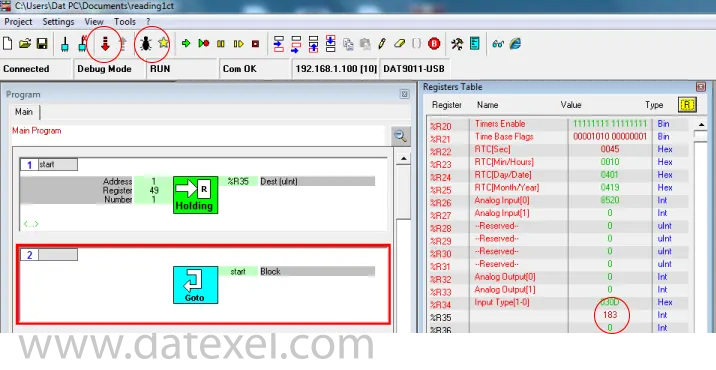

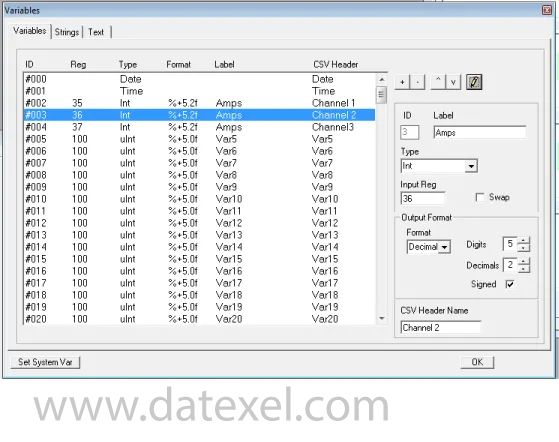

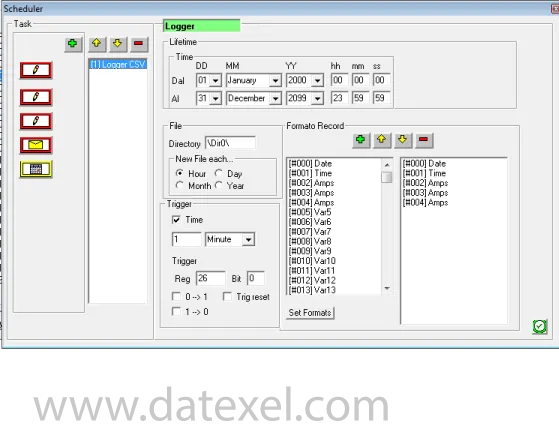

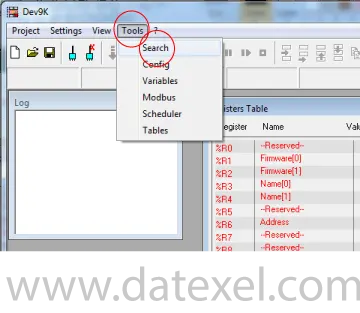

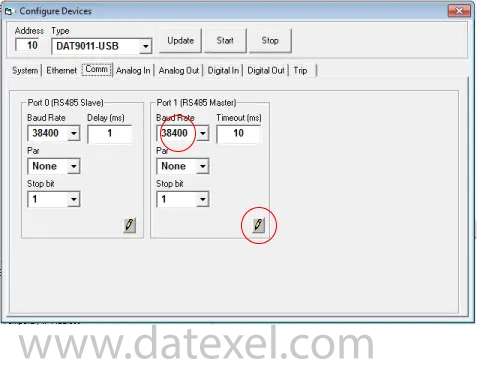

Communication options include RS485 (Modbus RTU) and Ethernet (Modbus TCP), with support for Master or Slave operation. Using Datexel’s free DEV9K software, you can map registers, configure logging (by time schedule and/or register trigger—including using a digital input as a start/stop), and apply processing such as linearization, scaling, averaging, square-root, comparisons, moves/shifts, trips, alarms, and timers.

Logged data can be retrieved by removing the SD/USB media for analysis on a PC or via the Ethernet port without interrupting operation. These loggers can be used alongside other Datexel devices, such as the DAT9550 remote display and the DAT3000 series analog/digital I/O modules. See the Downloads page for application notes, user guides, and the free DEV9K tool.

| INPUT | OUTPUT | POWER SUPPLY |

|---|---|---|

| mV, Volts, RTD, Resistance, Potentiometer, mA, Thermocouples. Digital Input. | Current 4-20mA, 0-20mA. 2 Relays. | Power Supply Voltage 10-30Vdc |

| Modbus Master/Slave RS485 | Modbus TCP Ethernet 10/100T | Reverse polarity protection 60Vdc |

| Modbus TCP Ethernet 10/100T | Modbus Master/Slave RS485 | |

| CURRENT CONSUMPTION | CONFIGURATION | ISOLATION |

| Between 45 and 170 mA | PC Programmable | Between Input/Comms/Power Supply 1500Vac. |

| EMC | HOUSING | TEMPERATURE |

| For Industrial environments | Material self-extinguishing | Operating Temperature 14°F +140°F -10°C +60°C |

| Immunity EN 61000-6-2 | Dimensions W x H x T 4" x 4 3/4 " x 7/8 " | Storage Temperature -40°F +185°F-40°C +85°C |

| Emission EN 6100-6-4 | 100 x 120x x 22.5 mm | Humidity (non condensing) 0-90% |

| Weight 3 oz 90 g |

| Input | |

| Analog Input | |

| Channel 0: | mV -100 to 100mV, Volts -100mV to 10V, Current 4-20mA, 0-20mA. RTD Pt100, Pt 1000, Ni100, Ni1000. Resistance 0-2000, Ohm. Potentiometer 20-2000 Ohm. Thermocouple J,K,R,S,B,E,T, N. |

| Channel 1: | mV -100 to 100mV. Volts -100mV to 10V. Current 4-20mA, 0-20mA. |

| Digital Input | 4 Channels. |

| Threshold | 0-3 Volts Off, 10-30V On. |

| Frequency | 300 Hz Maximum. |

| Output | |

| Analog | |

| Channel 1 and 2 | Current 4-20mA. |

| Digital | |

| Channel 1 and 2 | 2 Relays SPDT 2 Amp at 250 V. |

| Communication: | |

| RS485: | Port 1 Modbus RTU Master, Port 0 Modbus RTU Slave. |

| Ethernet: | Ethernet 10Base-T, Modbus TCP. |

| Power Supply: | Voltage 10 - 30 Vdc. Reverse polarity protection 60 Vdc. |

| Current Consumption: | 80 mA max. |

| Temperature rating: | Operative Temperature - 4°F +140°F -20°C +60°C Storage Temperature - 40°F +185°F -40°C +85°C. |

| Humidity: | (none condensing) 0-90%. |

| Housing: | Material self-extinguishing. |

| Dimensions: | W x L x H 4 x 4 3/4 x 1inch, 100 x 120 x 22.5mm. |

| Weight: | 7 oz 200 g. |

| EMC. | For industrial environments. |

| Immunity: | EN 61000-6-2. |

| Emission: | EN 61000-6-4. |

| Isolation: | 1500Vac, 50Hz, 1 minute. |

| Configuration: | PC Configurable with Ethernet. |

| Input. | Channel 0 | Channel 1 |

| Analog | ||

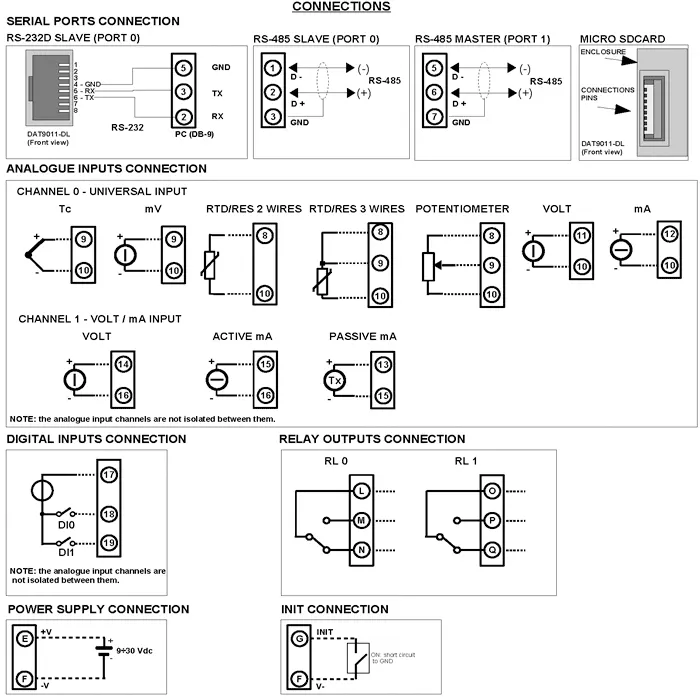

| Thermocouple | Positive 9 Negative 10 | N/A |

| mV | Positive 9 Negative 10 | N/A |

| RTD and Resistance 2 Wire | 8 and 10 | N/A |

| RTD 3 Wire | 8 and 10 Compensation 9 | N/A |

| Potentiometer | 8 and 10 Wiper 9 | N/A |

| Volts | Positive 11 Negative 10 | Positive 14 Negative 16 |

| mA | Positive 12 Negative 10 | N/A |

| mA Active | N/A | Positive 15 Negative 16 |

| mA Passive | N/A | Positive 13 Negative 15 |

| Digital | ||

| DI0 | 17 and 18 | |

| DI1 | 17 and 19 | |

| Output Analog | ||

| Current | Positive I Negative H | Positive J Negative H |

| Output Digital | ||

| Relay | Common L, NO M, NC N. | Common O, NO P, NC Q. |

| Power Supply (18-30Vdc). | Positive E Negative F. |

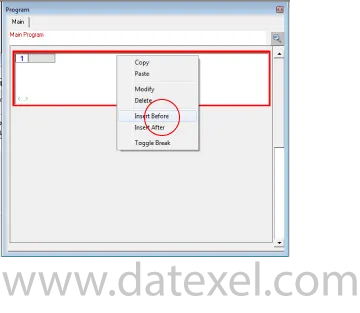

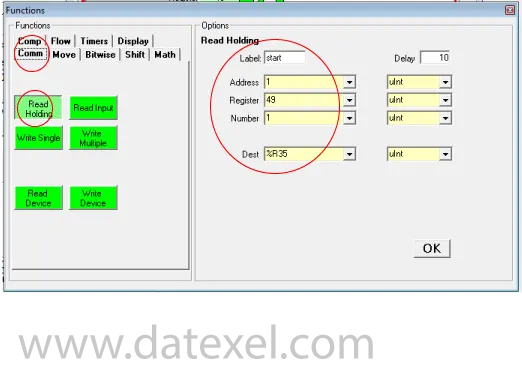

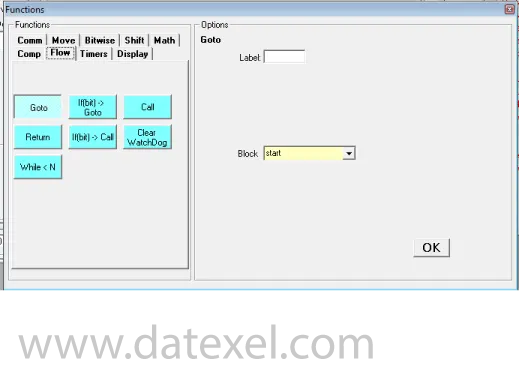

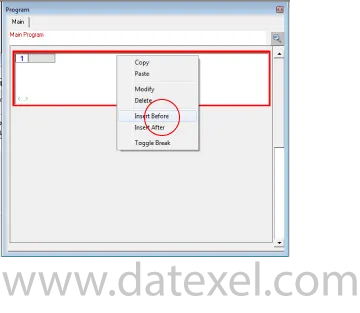

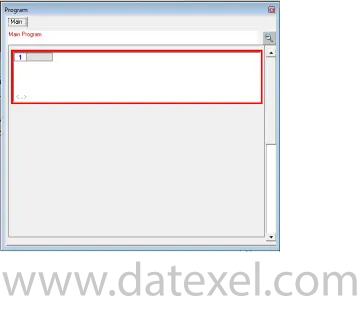

The program is made up with a group of function blocks. More information on these function blocks are available in the DAT9xxx user guide. Importantly the first function block must be labeled start and the last function block must be a goto function block with the command return to start. You can insert a function block anywhere in the program with the Insert Before or Insert After label.