Modbus RTU Master.

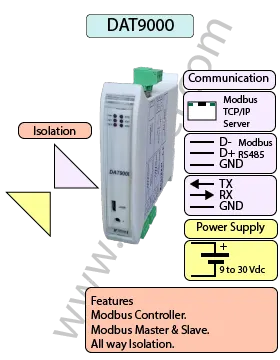

DAT9000

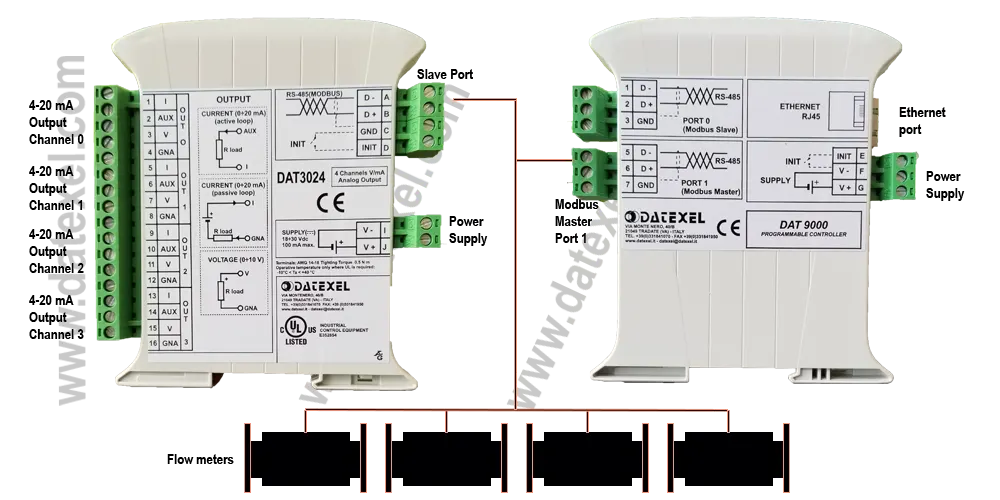

The DAT9000 Modbus RTU Master is a versatile data acquisition and controller unit designed for both Modbus Master and Modbus Slave operation. Equipped with an Ethernet 10 Base-T Modbus TCP interface and RS485 Master/Slave ports, the DAT9000 provides seamless integration with industrial networks and devices.

This unit can be programmed to read registers and execute logical or mathematical functions, offering features such as linearization, scaling, averaging, and square root extraction. These advanced capabilities make the DAT9000 ideal for applications requiring precise data handling and flexible process control.

The DAT9000 can also be paired with other Modbus devices. For example, it can work with the DAT3022 or DAT3024 modules to generate a 4-20 mA output signal from a Modbus-based flow meter or analyzer.

| INPUT | OUTPUT | POWER SUPPLY |

|---|---|---|

| Modbus Master/Slave RS485 | Modbus TCP | Power Supply Voltage 10-30Vdc |

| Modbus TCP | Modbus Master/Slave RS485 | Reverse polarity protection 60Vdc |

| CURRENT CONSUMPTION | CONFIGURATION | ISOLATION |

| Between 45 and 80 mA | PC Programmable | Between Input/Comms/Power Supply 1500Vac. |

| EMC | HOUSING | TEMPERATURE |

| For Industrial environments | Material self-extinguishing | Operating Temperature 14°F +140°F -10°C +60°C |

| Immunity EN 61000-6-2 | Dimensions W x H x T 4" x 4 3/4 " x 7/8 " | Storage Temperature -40°F +185°F-40°C +85°C |

| Emission EN 6100-6-4 | 100 x 120x x 22.5 mm | Humidity (non condensing) 0-90% |

| Weight 3 oz 90 g |

| Communication: | |

| RS485: | Port 1 Modbus RTU Master, Port 0 Modbus RTU Slave. |

| Ethernet: | Ethernet 10Base-T, Modbus TCP. |

| Power Supply: | Voltage 10 - 30 Vdc. Reverse polarity protection 60 Vdc. |

| Current Consumption: | 80 mA max. |

| Temperature rating: | Operative Temperature -4°F +140°F -20°C +60°C Storage Temperature -40°F +185°F -40°C +85°C. |

| Humidity: | (none condensing) 0-90%. |

| Housing: | Material self-extinguishing. |

| Dimensions: | W x L x H 4 x 4 3/4 x 1inch, 100 x 120 x 22.5mm. |

| Weight: | 7 oz 200 g. |

| EMC. | For industrial environments. |

| Immunity: | EN 61000-6-2. |

| Emission: | EN 61000-6-4. |

| Isolation: | 1500Vac, 50Hz, 1 Minute. |

| Configuration: | PC Configurable, DIP Switches. |

| Power Supply (18-30Vdc). | Positive G | Negative F. |

| INIT | Short pin E to F |

| RS-485 | Slave | Master |

| D- | Port 0 Pin 1 | Port 1 Pin 5 |

| D+ | Port 0 Pin 2 | Port 1 Pin 6 |

| GND | Port 0 GND | Port 1 GND |

| CVPROG | Front view | Micro USB |

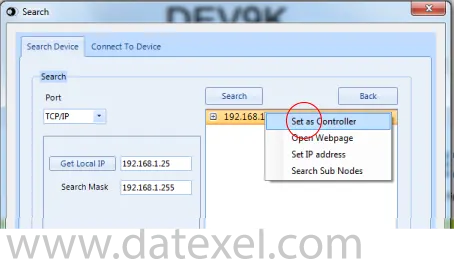

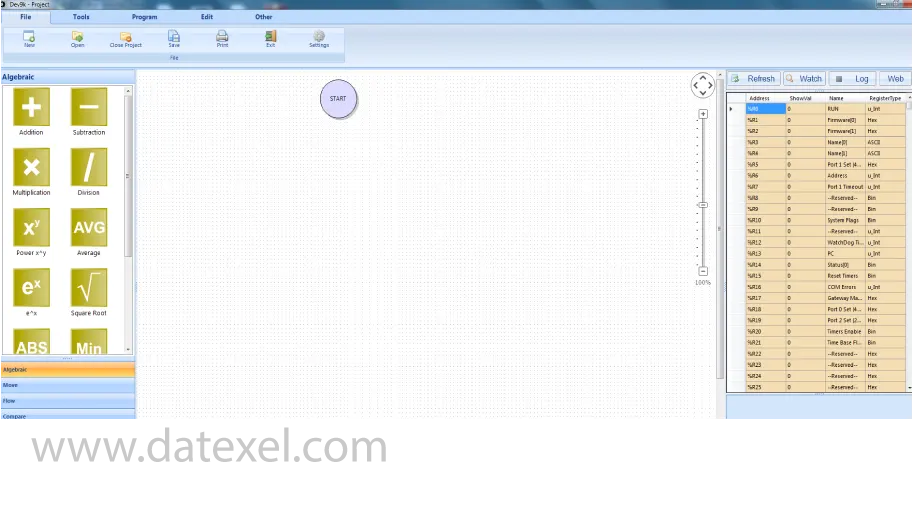

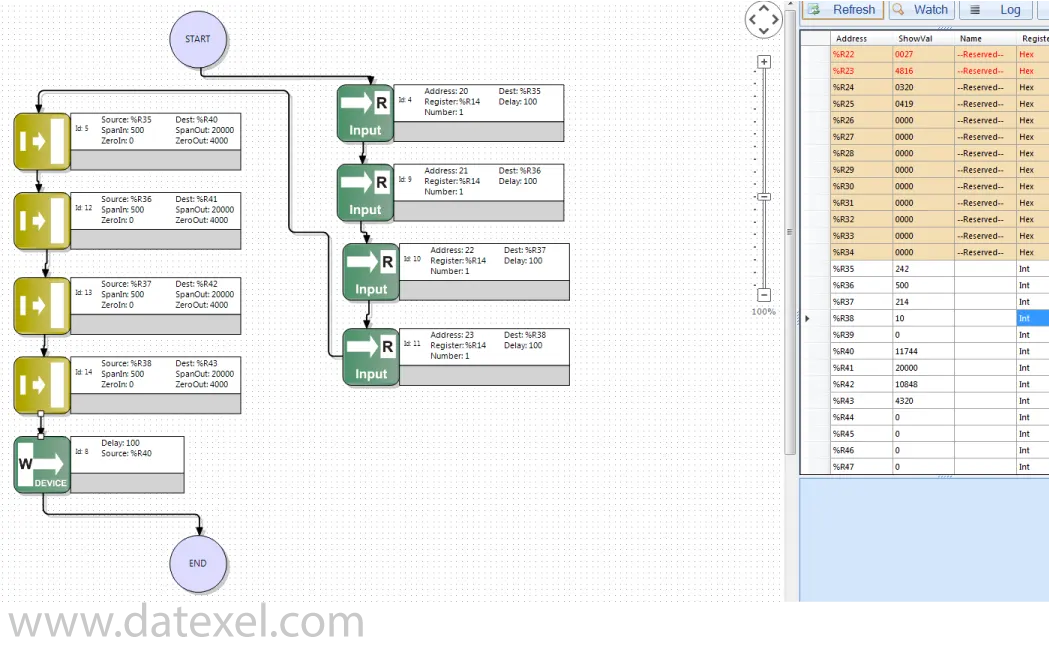

This is the main control screen for the Dev 9k Version 2. From here you can configure the Communication ports. Design and save new projects and open existing projects. In the left panel you have the function blocks. The center is the layout page for the program with the START position. On the right panel you have the registers. By Clicking the Refresh you can see what is stored in the registers.

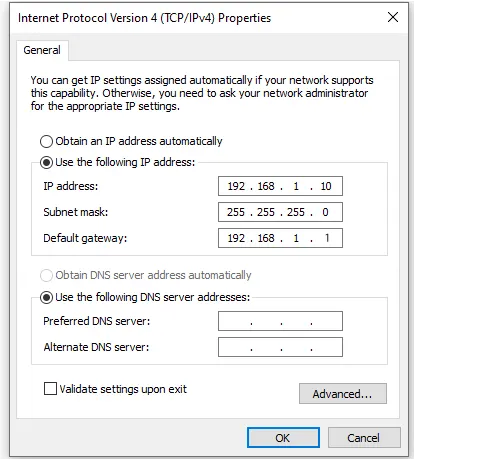

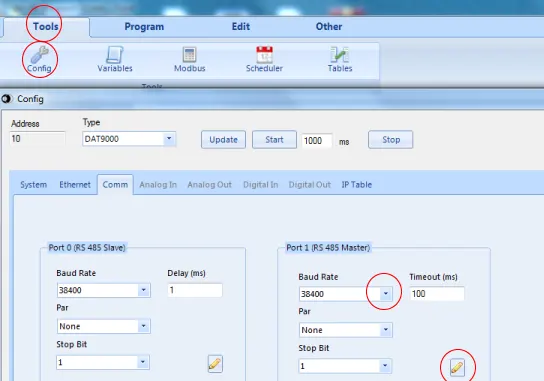

The Modbus Controller can only communicate with the Flow Meter and the DAT3024 if all the Modbus ports have the same Communication settings and different Addresses. The DAT9000 will be the Master so Port 1 (RS485 Master) needs to be set up.

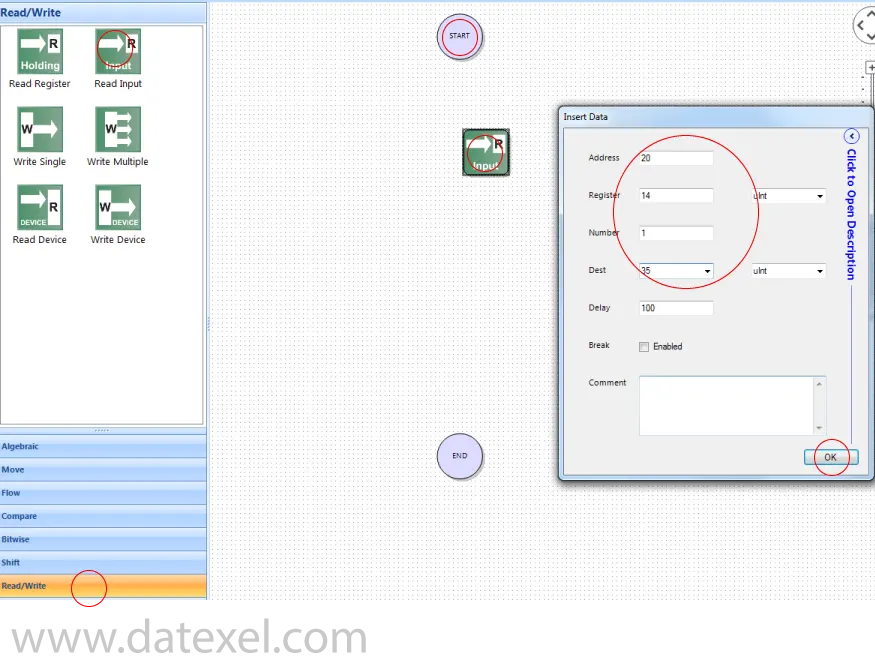

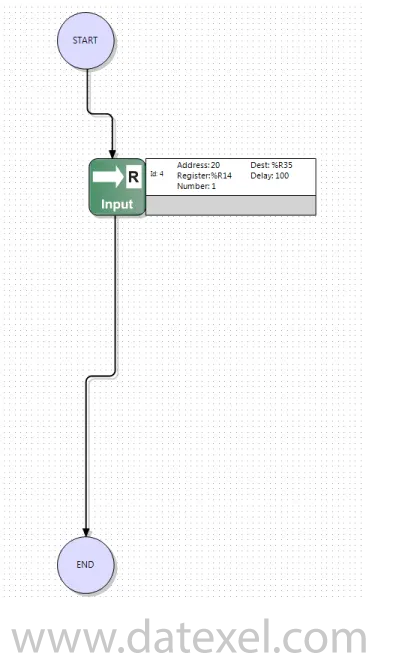

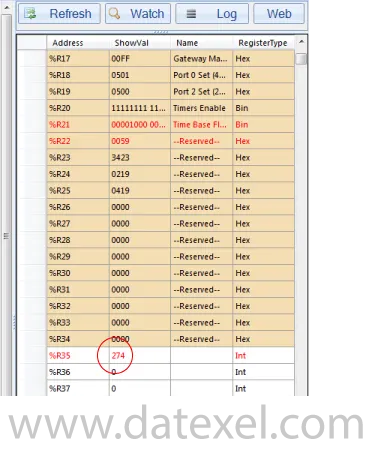

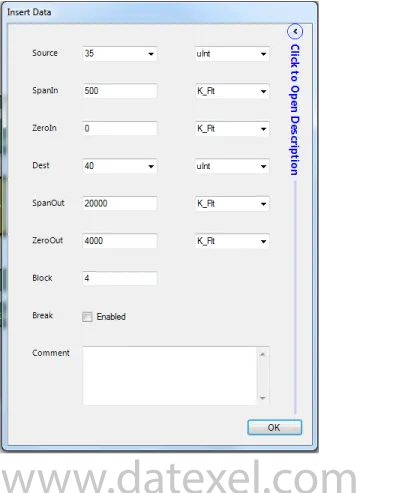

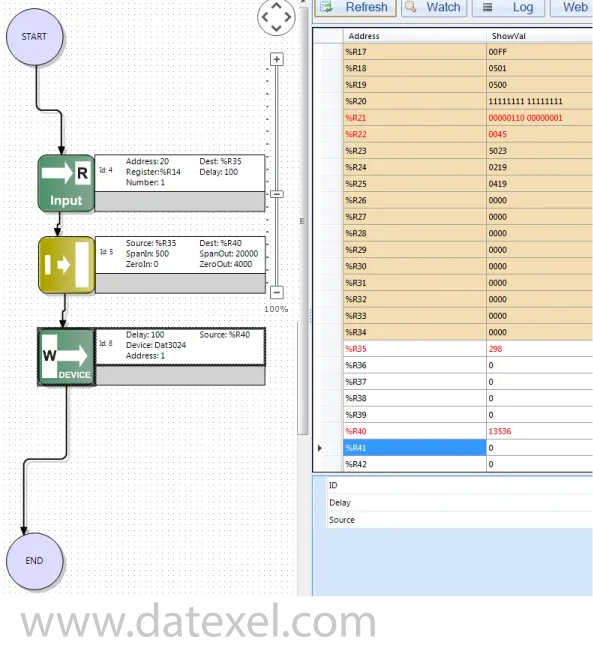

It is best to break down the project into parts. The first part will be to obtain the flow reading from one of the Flow Meters. The Flow Meter has Address 20( your flow meter will have a different Address), we are going to read register 40015 and place into the DAT9000 on register 35. We will be using a Read Input and must remove 40001 from the register table so the actual Register we use on the read Input Function Block will be 14.

The write function block writes the 4-20 mA to the DAT3024 Modbus RTU.

The DAT9000 is a data acquisition and controller unit that can operate as a Modbus RTU Master or Modbus Slave. It also includes an Ethernet 10 Base-T Modbus TCP interface and RS485 Master/Slave ports for industrial connectivity.

Yes. It supports Master or Slave operation. In many projects it polls field devices on RS485 (Master) while exposing selected registers to higher-level systems (Slave). Whether roles can be mixed simultaneously depends on your configuration and application design.

Yes. You can configure it to read data from Modbus RTU devices on RS485 and make that data available to Modbus TCP clients over Ethernet, or mirror specific registers between the two buses.

It supports logical and mathematical functions including linearization, scaling, averaging, and square-root extraction—useful for converting raw sensor values into engineering units or handling flow calculations.

Pair the DAT9000 with an output module such as the DAT3022 or DAT3024. The DAT9000 reads the Modbus register, applies any required scaling or square-root extraction, then writes the result to the output module to produce a 4–20 mA signal.

Protocol conversion between Modbus RTU and Modbus TCP, multi-instrument data aggregation, signal conditioning (e.g., scaling and linearization), and driving analog outputs via companion modules for plant systems that require a current loop signal.

Yes, the DAT9000 provides an Ethernet 10 Base-T Modbus TCP interface for easy integration with SCADA, PLCs, and HMIs.

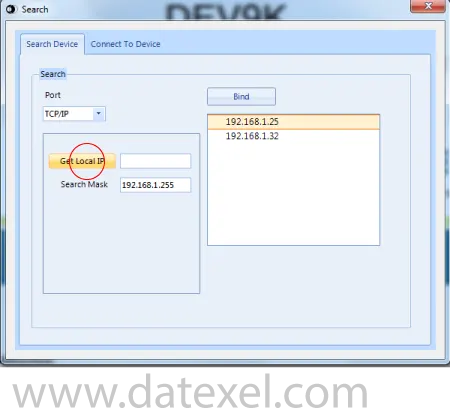

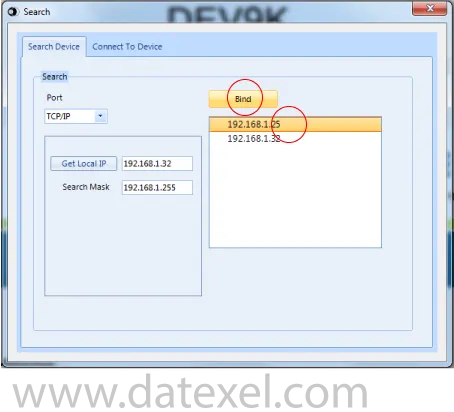

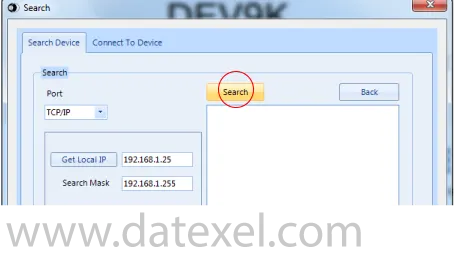

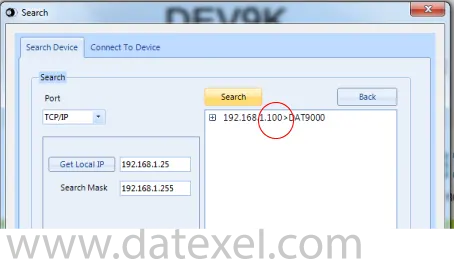

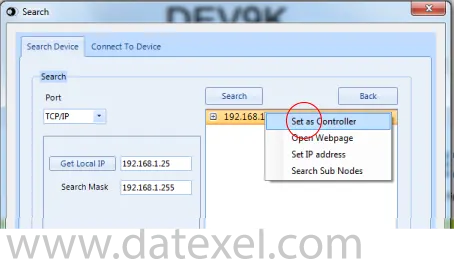

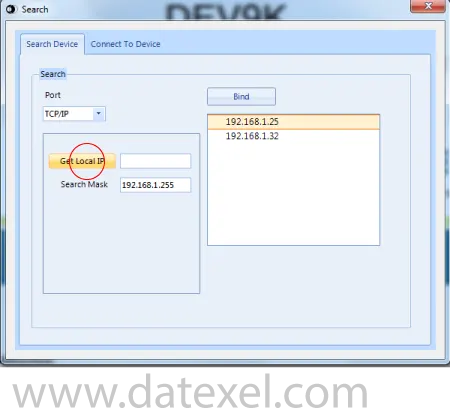

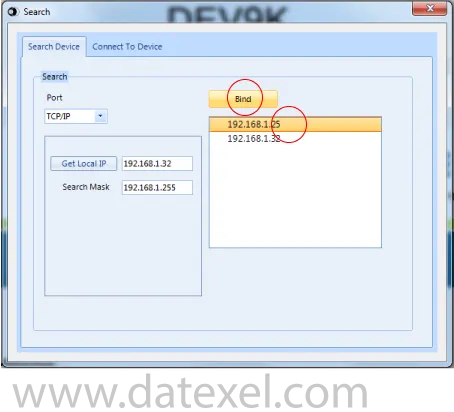

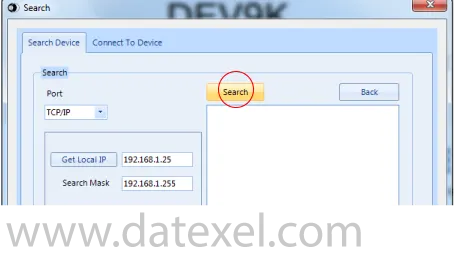

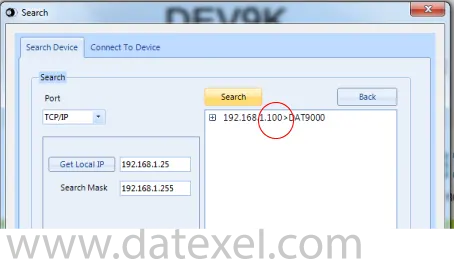

The DAT9000 is configured using the DEV9K development software, provided by Datexel free of charge. With DEV9K you can define Modbus maps (registers to read/write), set up logical and mathematical operations for scaling or calculations, and manage communication settings. The software includes step-by-step tools to simplify configuration for both Modbus RTU and Modbus TCP networks.

Yes. It works with standard Modbus RTU devices on RS485 and Modbus TCP systems over Ethernet, making it suitable for mixed-protocol environments.

Choose the DAT9000 when you primarily need data acquisition, Modbus protocol handling, and light processing (scaling, linearization, averaging, square-root). For broader control logic or extensive I/O on a single platform, a PLC may be more suitable.