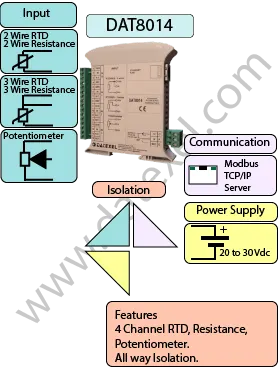

RTD, Potentiometer and Resistance to Modbus TCP converter

DAT8014

The DAT8014 is a powerful Modbus TCP server designed to convert up to four analog signals into digital format. With support for two- or three-wire RTDs and resistance sensors, the device offers reliable and accurate readings. Each input channel is electrically isolated, providing robust protection against ground loops and ensuring long-term stability and accuracy.

The integrated Watchdog Timer enhances system reliability by monitoring device operation, while the Ethernet interface allows real-time access to internal registers for both reading and writing data. The built-in web server makes it easy to monitor and configure the device remotely, simplifying system management.

Designed for industrial environments, the DAT8014 complies with UL 61010-1 and CSA C22.2 No 61010-1 standards, ensuring safe operation in both US and Canadian markets. The device is housed in a rugged, self-extinguishing plastic enclosure, with a slim 22.5 mm profile for space-saving DIN rail mounting.

With Dev9K software (available for free) for further configurability, the DAT8014 is a versatile and reliable solution for real-time temperature and resistance monitoring in various applications.

| INPUT | OUTPUT | POWER SUPPLY |

|---|---|---|

| RTD, Pt100, Pt1000, Ni100, Ni1000 | Modbus TCP Ethernet 10/100T | Power Supply Voltage 14-30Vdc |

| Resistance 0-500 Ohms. Resistance 0-2000 Ohms. Potentiometer 0-50000 Ohms. | Reverse polarity protection 60Vdc | |

| CURRENT CONSUMPTION | CONFIGURATION | ISOLATION |

| Between 60 and 115 mA | PC Programmable | Between Input/Comms/Power Supply 1500Vac. |

| EMC | HOUSING | TEMPERATURE |

| For Industrial environments | Material self-extinguishing | Operating Temperature 14°F +140°F -10°C +60°C |

| Immunity EN 61000-6-2 | Dimensions W x H x T 4" x 4 3/4" x 3/4 " | Storage Temperature -40°F +185°F-40°C +85°C |

| Emission EN 6100-6-4 | 100 x 120x x 22.5 mm | Humidity (non condensing) 0-90% |

| Weight 6 oz 160 g |

| Input: | |

| Channels | 4 Channels. |

| RTD | Pt100, Pt1000, Ni100, Ni1000 |

| Resistance | 0-500 Ohm, 0-2000 Ohm. |

| Potentiometer | 500 Ohm, 2000 Ohms. |

| Communication: | |

| Ethernet 10/100T: | Modbus TCP. |

| Power Supply: | 14 - 30 Vdc. Reverse polarity protection 60 Vdc. |

| Current Consumption: | 60 mA Standby 115 mA Max. |

| Temperature rating: | Operative Temperature 14°F +140°F -10°C +60°C Storage Temperature - 40°F +185°F - 40°C +85°C. |

| Humidity: | (not condensing) 0-90%. |

| Housing: | Material self-extinguishing. |

| Dimensions: | W x H x T 4 3/4 x 4 x 7/8 inch, 120 x 100 x 22,5mm. |

| Weight: | 6 oz 160 g. |

| EMC. | For industrial environments. |

| Immunity: | EN 61000-6-2. |

| Emission: | EN 61000-6-4. |

| Isolation: | Input, Each Channel, Power Supply, 1500Vac, 50Hz, 1 Minute. |

| Configuration: | PC Configurable. |

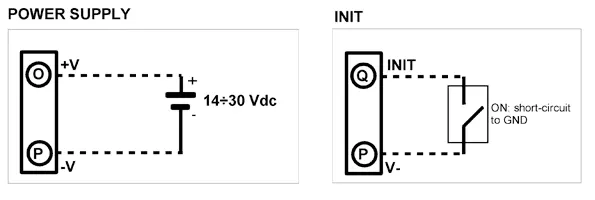

| Power Supply (18-30Vdc). | Positive O Negative P. |

| Init | Pin Q Init Gnd P |

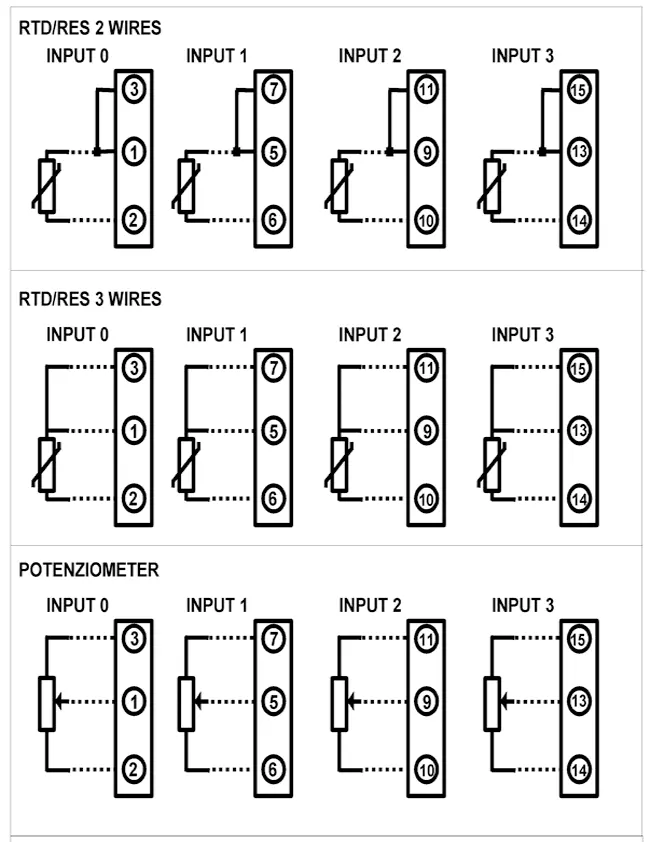

| RTD 2 Wire Input 0 | Sensor on 2 and 1 and Compensation on 3 |

| RTD 2 Wire Input 1 | Sensor on 6 and 5 and Compensation on 7 |

| RTD 2 Wire Input 2 | Sensor on 10 and 9 and Compensation on 11 |

| RTD 2 Wire Input 3 | Sensor on 14 and 13 and Compensation on 15 |

| RTD 3 Wire Input 0 | Sensor on 2 and 1 and Compensation on 3 |

| RTD 3 Wire Input 1 | Sensor on 6 and 5 and Compensation on 7 |

| RTD 3 Wire Input 2 | Sensor on 10 and 9 and Compensation on 11 |

| RTD 3 Wire Input 3 | Sensor on 14 and 13 and Compensation on 15 |

| Potentiometer Input 0 | Sensor on 3 and 2 and Wiper on 1 |

| Potentiometer Input 1 | Sensor on 7 and 6 and Wiper on 5 |

| Potentiometer Input 2 | Sensor on 11 and 10 and Wiper on 9 |

| Potentiometer Input 3 | Sensor on 15 and 14 and Wiper on 13 |

The DAT8014 supports a range of RTD sensors including Pt100, Pt1000, Ni100, and Ni1000. It can also accept inputs from potentiometers and resistance sensors up to 2000 Ohms. Custom ranges are available upon request.

The DAT8014 features 1500VAC galvanic isolation between inputs, Ethernet, and power supply, protecting against electrical interference and ground loops. Additionally, it is equipped with a Watchdog Timer system for monitoring device operation and ensuring reliable performance.

Yes, the DAT8014 has an integrated web server, allowing users to remotely monitor the status of analog inputs and configure key parameters via a web browser. The device can also be programmed remotely using the Modbus TCP protocol.

The DAT8014 is configured directly through its built-in web server, which allows users to access and adjust device settings via any web browser. This user-friendly interface simplifies the setup process without the need for external software.

Yes, the DAT8014 complies with UL 61010-1 and CSA C22.2 No 61010-1 standards, ensuring it meets the necessary safety requirements for both the US and Canadian markets. It is also CE and UKCA marked for broader international use.

The DAT8014 is designed for easy DIN Rail mounting and fits on standard EN-50022 rails. It also uses removable screw-terminal connections for the inputs and power supply, making installation and maintenance simple.